How to avoid a frozen sump pump in winter

Folks living in the colder climes often find that carrying out the sump pump testing procedure produces some movement in the sump water but no discharge from the pipe.

While it is possible that there may be debris inside the pump that is causing the blockage or the sump pump itself has frozen, most such cases occur because the water in the discharge pipe has frozen and thus blocked the exit.

While minor blockages can be mildly annoying, complete blockages are dangerous. Firstly, such blockages force the pump to run continuously without removing any water and can thus cause pump burnout.

Further, as water collects in the sump, the pump may overflow and flood the basement.

To ensure your basement and pump don’t fall prey to frozen pipes and the pump itself doesn’t freeze, we’ve provided a short Guide for learning how to avoid a frozen sump pump.Make Use of the Gradient

Freezing occurs mostly in the section of the pipe that sits outside the house and is thus exposed to the elements. While such exposure is inevitable, its effects on the water inside the discharge pipe are magnified if the water is not allowed to exit the pipe easily. This happens when the pipe’s angle does not match that of the slope of the ground.

If you are learning how to use a sump pump, you can simply attach the pipe in a manner that obeys the gradient of the ground around your house. If you have already installed the pipe, you may need to disconnect the pipe and then choose one that is capable of following the slope correctly.Use a wide/large pipe

When you disconnect the old pipe, you may consider using a large/wide pipe ie one with greater internal diameter, as the replacement. Ideally, this enhanced diameter should be much higher than that needed to remove even the highest amount of water during the monsoon.

If you’re wondering how a large pipe is linked to learning how to avoid a frozen pipe, let us add that a large pipe is never likely to be full of water. As such, even if the water is not drained out at any point of time and freezes due to the cold weather, it would not create a complete blockage.

Further, because water tends to flow out of any possible opening, the very fact that the pipe never completely fills up with water at any point acts as a means of ensuring that any water that is left over flows out of the pipe over time instead of freezing inside the pipe itself.

Keep Workload Low

While it may not be possible to reduce the sump pump’s workload in emergency situations, it is possible to take precautions beforehand that ensure that in cases of freezing inside the discharge pipe, the pump does not have to work itself to exhaustion.

This is all the more important because when the pipe is partially blocked, pumping out the same amount of water requires greater effort and this can put undue pressure on the pipe even when the water in the sump appears to be well within operating limits.

Some of the means of reducing pump workload are:

Carry out regular sump pump maintenance to ensure collection of debris does not reduce the efficiency of the motor.

Consider using a backup sump pump in addition to the primary one.

Keep the maximum head (height to which water is raised) low so that the pump can remove water faster and with less effort.

Heat the Sump Water

In case of freezing in the pipe or in the sump itself, it is advisable to use a heating rod to heat the sump water to a lukewarm temperature. To do so:

Disconnect the sump pump power supply.

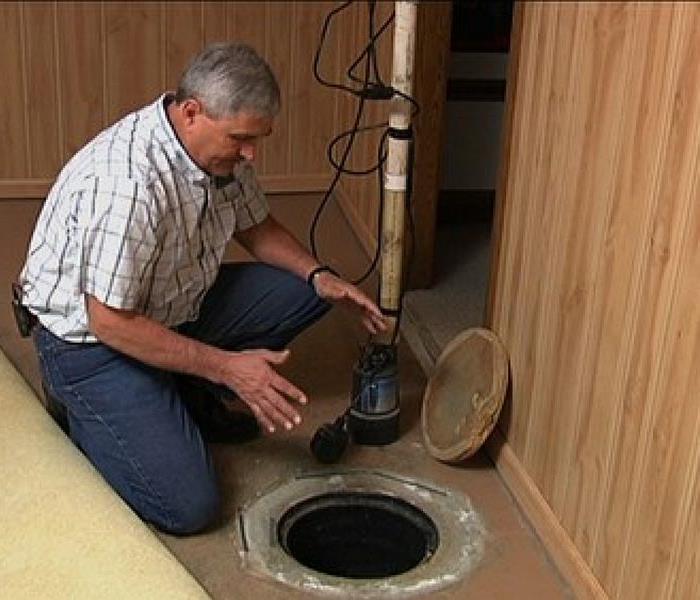

Remove the sump cover and note whether the sump water’s surface has completely frozen over. In case it has, use an ice pick to break the ice.

Ensure that the sump pump has proper electrical insulation and grounding. If either is absent, follow the alternative steps outlined after this set of steps.

Lower the heating coil/rod into the water. Ensure that it doesn’t rest against either the sump boundary or any sump pump component. Ideally you should hold the coil in place.

Connect the coil’s power supply and start it. Use a thermometer to measure the temperature of the water in the sump.

When the water temperature has risen by about 20-30 degrees Celsius, stop the coil and remove it

Reconnect the sump pump power supply and wait for a while. The hot water would melt the ice in the sump and the pipe and this in turn would make water flow normal, at least for the time being.

If your pump is not properly insulated, DO NOT lower the coil into the water. Instead:Heat water in a bucket using the coil.

While the water heats, break any ice that may be lying on the top of the water in the sump.

Once heating is complete, unplug and remove the coil.

Pour the hot water from the bucket gently into the pump until about 1/4th of the sump remains above the water level.

Start the sump pump and wait for the hot water to melt the ice.

Once the sump pump has removed some of the water, pour out some more hot water. You may reheat the water still in the bucket if it has become cold.

Important notes :

Avoid pouring water too fast. If too much hot water interacts with cold water, excess steam may be produced. While not harmful, such steam may reduce visibility and force you to stop the process.

There is no need to empty the bucket into the sump. Once you feel the pump is able to remove water at a normal pace, it is time to stop the process.

Sump pumps are not designed for working with extremely hot water. Heating water too much might ruin the internal components of the sump pump.

Do not touch the water with your hand while the coil is in the sump. In fact, you should wear rubber gloves while lowering the thermometer or use a non-conducting stick to check the temperature.

If you don’t adhere to these requirements, you may get a nasty electrical shock!Freezing of Internal Sump Pump Components

Freezing of the sump pump itself is extremely rare since the oil inside the motor chamber is insulated from changes in outside temperature and freezing in the discharge or impeller can be removed using the above method.

If you do suspect freezing of the core components of the pump or wish to learn how to avoid a frozen sump pump, you can:

Remove the pump from the sump after disconnecting the power supply.

Check for frozen water inside the impeller or discharge. Use an ice pick or similar instrument to remove such ice or frozen debris. If nothing is frozen, you can check for blockages that might freeze over during the winter.

Move the float gently to ensure that there is no jamming due to freezing. If it does not move easily, remove ice or debris from the shaft and/or the float itself till movement becomes normal.

Note whether the insulation of the motor compartment has been damaged anywhere. Such damage may have led or in the future may lead to the motor lubricant oil or coating oil freezing over.

Leave the sump pump in a warm area for some time. You can also leave it near a heat source that does not involve flames. Even if there is no actual freezing, this step would help melt any blockages within the pump that might freeze later.

Replace the pump in the sump and check whether the pump is working normally.Note : Never try to heat the pump or any of its components directly as this may lead to the motor exploding or the lubricating oil catching fire. Conclusion

Freezing is not included among the most common sump pump issues and solutions because it affects only those in particular climatic situations and that too, not very often. However, if you do find your sump pump or any of its components frozen, it is advisable to carry out the above procedures and so ensure that as and when the rains come, your pump is ready to handle them. On the other hand, if you believe the pump can freeze sometime in the future and would like to learn how to avoid a frozen sump pump, you should assess the possible threats to your pump and discharge pipe during the autumn or early winter so as to give yourself adequate time to carry out the necessary procedures.